Led by Dr Arun Arjunan in support with John Robinson and Dr Ahmad Baroutaji

The research undertaken by the AMFM group spans both fundamental and applied engineering at the interface of additive manufacturing (also known as 3D printing) and the next generation of functional materials. The group’s research is focused on enabling future digital fabrication to combine additive manufacturing, materials, and structures to achieve unprecedented mechanical, biological, acoustic, thermal, and electrical properties.

Keywords: Additive manufacturing; 3D printing; in-situ alloying; process parameter development; metamaterials; biomaterials; energy materials; tissue engineering

For information regarding the AMFM group, research collaborations and PhD opportunities email amfm@wlv.ac.uk, alternatively you can contact the research group lead Dr Arun Arjunan at a.arjunan@wlv.ac.uk

Research Focus

The research activities of the group are supported by a range of interdisciplinary academic specialists, post-docs, research technicians and PhD students. The group works closely with business, other research institutions, AMT/8 Additive manufacturing BSI standards development committee, and other policymakers to translate the research for improving industrial competitiveness, societal benefits, commercial use, spinoff companies and better products. Through active collaboration with both academic and commercial enterprises, the AMFM group has realised new opportunities that go beyond the current state of the art.

The core research carried by group is focussed on the investigating the underpinning processes, materials, and computational methods for multifunctional additive manufacturing for the development of fully functional materials and systems as seen below.

Additive Manufacturing of Functional Materials

Summary of the research activities of the AMFM group

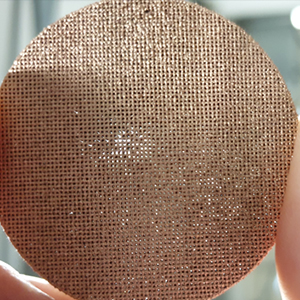

In-situ alloying and process parameter development for the additive manufacturing of custom materials acting as a key enabler for Industry 4.0 and the digital supply chain revolution.

Including:

- Algorithmic parameter development

- Chamber constraints

- Custom gas mixes

- Melt-pool monitoring

Development of metamaterials that offer unprecedented mechanical, acoustic, thermal, and biological properties transcending the next generation of functional materials.

Including:

- Mechanical metamaterials

- Acoustic metamaterials

- Biological metamaterials

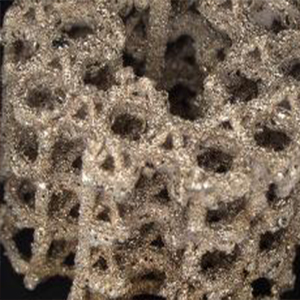

- Auxetic, TPMS, hybrid

Additive manufacturing for personalised medicine including biomaterials for patient-specific implants, personalised tissue engineering scaffolds and functional antimicrobial and bioactive materials for solving challenges associated with precision medicine, implant unloading, pandemic preparedness and antimicrobial resistance (AMR).

Including:

- Patient specific implants

- Tissue engineering scaffolds

- Antimicrobial materials

Additive manufacturing of energy materials for future energy-absorbing architectures, 3D printed electrical machines, high-efficiency battery cooling, energy storage devices, fuel cells and heat recovery systems.

Including:

- Energy absorbing

- Electrical machines

- Advanced thermal materials

EOS GmbH, BOC Ltd; 6DMe UK, University of Sussex, University of Bristol, ESTIA France, Catholic University of Valencia

Recently featured research in media

More Information

1. Dr Arun Arjunan, Reader in Additive Manufacturing of Functional Materials (Lead)

2. Dr Ahmad Baroutaji, Senior Lecturer and Course Leader (Co-lead numerical modelling)

3. John Robinson, Senior research technician and PhD researcher (Co-lead additive manufacturing)

4. Iain Lyall, Lecturer, and principal technician

5. Neil Basini, Research technician and PhD researcher

6. Dr Syed Hasan, head of school of engineering

7. Dr Loganathan T. Govindaraman, post-doc research fellow

8. Dr Peter Wardle, Principal lecturer in engineering

9. Dr Adriano Cerminara, Lecturer in Engineering

10. Dr David Adebayo, Senior Lecturer in Engineering

11. Dr Fideline Tchuenbou-Magaia, Senior Lecturer in Engineering

12. Dr Kiran Gulia, Senior Lecturer in Engineering

13. Aaron Vance, PhD researcher

14. Gurpal Singh, PhD researcher

15. Gustavo Fazalzadeha, PhD researcher

16. Tharumal Wanniarachchi, PhD researcher

17. Manpreet Singh, PhD researcher

18. Martin Appiah, PhD researcher

19. Suhaib Zahid, PhD researcher

20. Terrenoir Laurent, PhD researcher

21. Edward Andrews, PhD researcher

Interdisciplinary expertise

22. Prof Craig Williams, Professor of Meso And Microporous Materials

23. Dr Wayne Heaselgrave, Senior Lecturer in Biomedical Engineering

24. Enas Al-Ani, post-doc research fellow

25. Dr Marina Bock Montero, Senior Lecturer in School of Architecture and Built Environment

26. Dr Shashank Gupta, Senior Lecturer in School of Architecture and Built Environment

Additive Manufacturing

- EOS M270

- EOS M290

- Stereolithography

- Fused deposition modelling (FDM)

- Melt-pool Monitoring

- Powder characterisation

- Heat treatment

- High speed machining

- Wire EDM

Characterisation and part validation

- Confocal microscopy

- Scanning Electron Microscopy (SEM)

- Energy Dispersive Spectroscopy (EDS)

- X-Ray Diffraction Analysis (XRD)

- X-Ray computed tomography (X-ray CT scanning)

- Quasi-static material testing (compression, tension, bending, shear)

- Impact testing

- Surface roughness and toughness

- Fatigue testing

- 3D Scan reverse engineering

- Thermal material testing

- Tran, A. Baroutaji, Q. Estrada, A. Arjunan, H. Le and NP. Thien. Crashworthiness analysis and optimization of standard and windowed multi-cell hexagonal tubes. Struct Multidisc Optim (2021). DOI: https://doi.org/10.1007/s00158-020-02794-y

- Baroutaji, A. Arjunan, M. Ramadan, J. Robinson, A. Alaswad, MA. Abdelkareem and AG. Olabi. Advancements and prospects of thermal management and waste heat recovery of PEMFC. International Journal of Thermofluids (2021) 100064. DOI: https://doi.org/10.1016/j.ijft.2021.100064

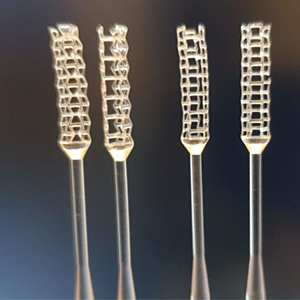

- Arjunan, S. Zahid, A. Baroutaji and J. Robinson. 3D printed auxetic nasopharyngeal swabs for COVID-19 sample collection. Journal of the Mechanical Behavior of Biomedical Materials, 114 (2021) 104175. DOI: https://doi.org/10.1016/j.jmbbm.2020.104175

- Robinson, A. Arjunan, M. Stanford, I. Lyall and C. Williams. Effect of silver addition in copper-silver alloys fabricated by laser powder bed fusion in situ alloying. Journal of Alloys and Compounds (2020) 157561. DOI: https://doi.org/10.1016/j.jallcom.2020.157561

- Baroutaji, A. Arjunan, M. Stanford, J. Robinson and AG. Olabi. Deformation and energy absorption of additively manufactured functionally graded thickness thin-walled circular tubes under lateral crushing. Engineering Structures, 226 (2021) 111324. DOI: https://doi.org/10.1016/j.engstruct.2020.111324

- Arjunan, J. Robinson, Enas Al Ani, W. Heaselgrave, A. Baroutaji and CJ. Wang. Mechanical performance of additively manufactured pure silver antibacterial bone scaffolds. Journal of the Mechanical Behavior of Biomedical Materials, 112 (2020) 104090. DOI: https://doi.org/10.1016/j.jmbbm.2020.104090

- Robinson, M. Stanford and A. Arjunan. Correlation between selective laser melting parameters, pore defects and tensile properties of 99.9 % silver. Materials Today Comm., 25 (December 2020), 101550. DOI: https://doi.org/10.1016/j.mtcomm.2020.101550

- Arjunan, M. Singh, A. Baroutaji and CJ. Wang. Additively manufactured AlSi10Mg inherently stable thin and thick-walled lattice with negative Poisson’s ratio. Composite Structures, (2020) 112469. DOI: https://doi.org/10.1016/j.compstruct.2020.112469

- Robinson, M. Stanford and A. Arjunan. Stable formation of powder bed laser fused 99.9% silver. Materials Today Comm., 24 (September 2020), 101195. DOI: https://doi.org/10.1016/j.mtcomm.2020.101195

- Nikkhah, A. Baroutaji, Z. Kazanci and A. Arjunan. Evaluation of crushing and energy absorption characteristics of bio-inspired nested structures. Thin-Walled Structures 148 (2020) 106615. DOI: https://doi.org/10.1016/j.tws.2020.106615

- Praveen and A. Arjunan. Effect of nano-Al2O3 addition on the microstructure and erosion wear of HVOF sprayed NiCrSiB coatings. Materials Research Express, (2020) 7, 015006. DOI: https://doi.org/10.1088/2053-1591/ab5bda

- Arjunan, M. Demetriou, A. Baroutaji and CJ. Wang. Mechanical performance of highly permeable laser melted Ti6Al4V bone scaffolds. Journal of the Mechanical Behavior of Biomedical Materials, (2020) 103517. DOI: https://doi.org/10.1016/j.jmbbm.2019.103517

- Praveen and A. Arjunan. Parametric optimisation of high-velocity oxy-fuel nickel-chromium-silicon-boron and aluminium-oxide coating to improve erosion wear resistance. Materials Research Express, volume 6 (2019) 096560, issue 9. DOI: https://doi.org/10.1088/2053-1591/ab301c

- Arjunan. Targeted sound attenuation capacity of 3D printed noise cancelling waveguides. Applied Acoustics, volume 151 (2019) pp. 30-44. DOI: https://doi.org/10.1016/j.apacoust.2019.03.008

- Arjunan. Acoustic absorption of passive destructive interference cavities. Materials Today Comm., 19 (2019), pp. 68-75. DOI: https://doi.org/10.1016/j.mtcomm.2018.12.012

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-18-19/iStock-163641275.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/250630-SciFest-1-group-photo-resized-800x450.png)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-18-19/210818-Iza-and-Mattia-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images/Maria-Serria-(teaser-image).jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/241014-Cyber4ME-Project-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-18-19/210705-bric_LAND_ATTIC_v2_resized.jpg)