POLICY/PROCEDURE

The University of Wolverhampton (University) has a statutory duty to ensure, so far as is reasonably practicable, the health, safety, and welfare of all its employees, students, visitors, and contractors.

A risk assessment is an important step in protecting all members of the University community, as well as complying with the law. It enables the University to focus on the significant risks in the workplace, with the potential to cause harm. In many instances, straightforward measures can readily control risks, for example, ensuring spillages are cleaned up promptly, so people do not slip, or cupboard drawers kept closed to ensure people do not trip. For most, that means simple, cheap, and effective measures to ensure our community is protected.

The legal duty to undertake risk assessments is explicitly required by regulation 3 of the Management of Health and Safety at Work Regulations 1999 which states:

“Every employer shall make a suitable and sufficient assessment of:

- The risks to the health and safety of their employees to which they are exposed whilst they are at work; and

- The risks to the health and safety of persons not in their employment arising out of or in connection with the conduct by them of their undertakings”

In summary this means that the risks to the health and safety of employees and anyone else, resulting from the work activity must be risk assessed.

This document is issued under the University’s Health and Safety Policy. It will be reviewed on a triennial basis.

In addition to the legal requirements, there are several reasons why responsible employers should use risk assessments, including:

- Reduction in accidents, injuries, ill health, and fatalities.

- Increases in quality standards, efficiency, and productivity.

- Reduction of costs of injuries and ill health.

- Improved targeting of resources.

- Good management practice.

This policy applies to all employees of the University, including those who are within a probationary period.

University staff who fail to adhere to the terms of this policy may be subject to disciplinary action, up to and including dismissal.

The risk assessment process is a careful examination of what in your work, could cause harm to people (staff, students, members of the public, contractors etc.). This enables you to decide whether you have taken enough precautions or should do more to prevent harm. The aim is to make sure that no one gets hurt or becomes ill.

Accidents and ill health can ruin lives and impede the effective operation of the University.

It is important to decide whether a hazard is significant, and whether you have mitigated it with satisfactory precautions, so that the risk of harm is low. The meanings of the terms “hazard” and “risk” are often confused, and their meanings are frequently transposed. The meanings of both are set out below:

- Hazard: is something having the potential to cause harm (e.g., chemicals, working from ladders, electricity, etc.). However, it is not just the hazard it is how the hazard could cause harm e.g., electricity – this could be ‘electric shock’ or even ‘fire’, dependent on the circumstances. Always think about how the hazard can cause harm.

- Risk: is the probability or likelihood, great or small that injury will result from the hazard.

It is the responsibility of the Deans and Directors, to ensure that the risk assessments required by these regulations are carried out within their Faculty/Professional Service Department. They should nominate appropriate members of staff in each work area to carry out the risk assessments using the appropriate forms, see appendix A.

The findings which cannot be controlled locally, should then be reported to the appropriate Line Manager, who will take the necessary action to control the risk in an appropriate timeframe, depending on whether the risk is low, medium, or high. If the action required is outside the remit of the Line Manager’s authority, the matter must be escalated to the appropriate Dean or Professional Service Director. The Dean or Director has the final responsibility for health and safety within the Faculty/ Department.

It is important not to overcomplicate the risk assessment process, as usually hazards are few and simple. In many cases the risks present which are likely to cause harm in the workplace will already be known and if so, the reasonable precautions already in place in avoid injury should be assessed.

It is essential to identify whether a hazard is ‘reasonably foreseeable’ or not, that is, could you have reasonably expected it to happen. If it is reasonably foreseeable, it should be addressed.

Some hazards identified may require a more specialised risk assessment to be carried out, including, the presence of chemicals, fire, manual handling/lifting etc. If this is the case, it is important that the appropriate individuals are involved in the assessment.

The University risk assessment process includes the following steps:

- List the hazards (Hazards description)

- List the individuals at risk

- Evaluate the risk (Initial assessment)

- Control measures

- Residual risk

- Further action required

- Record of findings

This process is based around the Health and Safety Executive (HSE) Guidance – Five steps to risk assessment. However, the University procedure is a six-stage process as the assessment looks at the initial risk, as well as the residual risk, which is the risk level when all existing controls have been considered.

The risk assessment process is a requirement under several additional Health and Safety legislations, including the following:

- Control of Substances Hazardous to Health (COSHH) 2002, (as amended).

- Control of Noise at Work Regulations 2005.

- The Control of Asbestos Regulations 2012.

- The Management of Health and Safety at Work Regulations 1999.

- The Health and Safety (Young Persons) Regulations 1997.

- The Health and Safety (Display Screen Equipment) Regulations 1992.

- The Manual Handling Operations Regulations 1992 (as amended).

- The Personal Protective Equipment at Work Regulations 1992 (as amended 2022)

- The Ionising Radiations Regulations 2017.

- Regulatory Reform (Fire Safety) Order 2005.

Risk assessments are required in some other ‘less obvious’ aspects of work activity, which may include situations such as:

- Lone working.

- Pregnant workers.

- Field trip safety.

- Student Placements.

- International travel.

A step-by-step guide to completing the risk assessment form.

List the Hazards (Hazard Description)

Walk around your workplace and look at what could reasonably be expected to cause harm. Ignore the minor hazards l and concentrate only on significant hazards, which could result in serious harm or affect several people. Seek the views of other you employees or their representatives, as they may have noticed hazards, which are not immediately obvious. It is advisable to consult manufacturers’ instructions or hazard data sheets to assist with identifying hazards and put the risks into perspective. The following examples can be used as a guide:

- Mechanical hazards (e.g., crushing, shearing, cutting, falling objects entanglement)

- Electrical hazards (e.g., short circuit, direct contact, indirect contact, source of ignition)

- Radiation hazards (e.g., lasers, electro-magnetic effects, ionising/non-ionising radiation)

- Hazardous substances (e.g., Toxic gas/mist/fumes/dust, flammable fluids, biological substances)

- Work activity hazards (e.g., highly repetitive actions, mental overload/stress, poor workplace design, lifting and handling, proximity to other requiring ‘social distancing’ etc.)

- Work environment hazards (e.g., noise, vibration, heating, lighting, ventilation)

This is not a comprehensive list of hazards; it should be used as a guide.

|

Guidance: Always remember the following:

|

List those at risk (people at risk)

It is important to consider who may be affected by the hazards present. The individuals most likely to be at risk, are those that spend the most time in the workplace, however it is equally important to consider people who may not be in the workplace all the time, e.g., cleaners, visitors, contractors, maintenance personnel, students etc.

Members of the public and people who may share your workplace should be included in the list, if there is a chance they could be hurt by your activities. Some categories of workers may require a more detailed assessment because of their condition, including expectant and nursing mothers, disabled and young persons, or lone workers.

Evaluate the risks (Initial assessment)

The next stage of the assessment, once the hazards and people at risk have been identified, is to establish the level of risk before any control measures have been put into place. The process is as follows:

- Work environment hazards (e.g., noise, vibration, heating, lighting, ventilation)

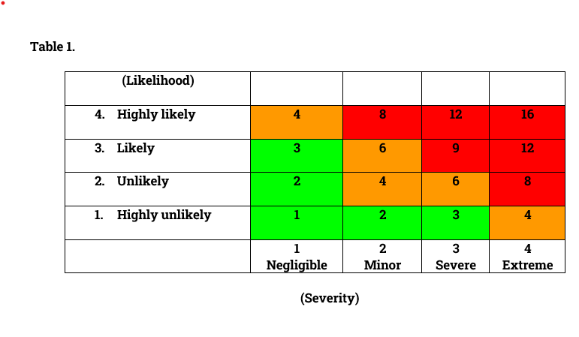

- Rate the likely severity (S) of any hazard being realised on a scale of 1 to 4 (1 is Negligible, 4 is Extreme or Fatal).

- Multiply the severity and the likelihood to find the risk factor (R), for example a severity of 3 and a likelihood of 2 would give a risk factor of 6.

- Assess if the level of risk is acceptable or not.

At this stage you are assessing the Risk Factor without any control measures in place. Once control measures are put in place, the risk assessment should be repeated to assess the residual risk.

When calculating the risk factor, you should use table 1 below as a guide. The table provides a ‘heat map’ which will indicate using the colour, hazards that are currently under control, or if further action is required.

Control Measures

After evaluating the initial risks, you should then review what existing controls are in place or are being put in place. When considering control measures the most important starting point is implementing the ‘Hierarchy of Control’ (see below), which will assess the different ways a hazard can be reduced or removed.

This process also highlights the point that whilst providing Personal Protective Equipment (PPE) is a consideration, as a control measure it should always be down the list of options. In line with the risk hierarchy of control.

The Hierarchy of Control

- Elimination or avoidance (i.e., does the process/activity have to be carried out).

- Substitution (i.e., what alternatives can be used, for example, chemicals, processes, equipment).

- Controlling risks at source (i.e., can the hazards be designed out).

- Separation and isolation (i.e., physically separating or isolating the process/activity, ‘socially distance’ from colleagues or students).

- Safe working procedures (i.e., are these in place and known to individuals taking part).

- Training, instruction, and supervision (i.e., are all staff competent enough to carry out their duties).

- Personal Protection Equipment - PPE (the last resort but also to supplement some of the other controls).

Other considerations

- Welfare facilities

- First aid facilities

- Emergency procedures

The ‘Hierarchy of Control’ should always be used in the order it appears on the list, meaning eliminating or avoiding the hazard should always be considered first. Risk assessors should then work down the list and introduce the most appropriate means of controlling the risk. Once again it must be stressed that issuing PPE is not the first option but is the last measure that should be considered. The best form of control is usually to implement the most appropriate measures from one to four, then introduce the measures from five to eight to re-enforce the controls.

|

Guidance: When controlling the risks, apply these principles, if possible, in this order:

|

The Residual Risk

Once all the control measures have been put in place, the remaining or residual risk must then be assessed. This will follow the same process as the ‘Initial Assessment’ with the result being a risk factor (R) score i.e., L x S=R. The residual risk is the risk of the control measures failing and not the risk of an accident happening.

Even after all precautions have been taken, usually some risks remain. What must be decided for each significant hazard is whether the remaining risk is, high, medium, or low.

This will determine whether any further controls are still necessary, to make the process as safe as is reasonably practicable. It is important at this point that the risk assessment is completed honestly, for example, a low-risk score should not be given deliberately, to avoid further action.

It should be noted that if the process is hazardous, giving it a low score on an assessment form will not make the process any safer. This must be done through acting upon the findings of your initial assessment.

Further Action Required

Once the Residual Risk Factor (R) has been established, further actions or controls may still be required. Further action could include eliminating or substituting a process/substance etc., or introducing safe systems of working or additional training, instruction, or information to employees.

When actions/comments are identified, responsibility for carrying these actions must be assigned to an individual or group of individuals. Ownership for different parts of the risk assessment process must be given and individuals should be informed of their expectations and responsibilities placed on them, including when they should be completed. The date set for implementing any remedial actions should be a realistic so the action can be achieved.

|

Guidance: If you have assigned actions to other people in your risk assessment, ensure they are aware of the risk assessment. |

Record your findings – significant risks

Significant findings of the assessment must be recorded. This means recording the more significant hazards and the most important conclusions. This can be illustrated by the following examples:

- Electrical installations: insulation and earthing checked and found sound.

- Fume from welding: local exhaust ventilation provided and regularly checked.

If the risks will impact on any other employees, you must inform them of your findings.

You must keep a copy of your risk assessment, as this will confirm when the activity took place, the findings considered and who was involved in the process.

|

Guidance: Remember your risk assessment should be suitable and sufficient, this means you should show that:

|

Monitoring and Review

Monitoring and review is an important stage in the process, however it is often overlooked. It will provide an opportunity to review the assessment in the light of changes to personnel, procedures, equipment, and facilities. It will also prevent a possible situation where the risk assessment is completed and then never reviewed again until perhaps, an untoward occurrence which could take place. This could lead to potential risks that if overseen can result in possible disciplinary action resulting in possible litigation.

The individual who will be performing the review of the risk assessment should be identified and when this will take place.

Risk Assessment – Good practice and responsibilities

For the risk assessment to be effective, there are some areas of good practice that should be included in the process, including:

- Undertake the risk assessment as a group activity.

- Always involve individuals at risk and in control in the risk assessment.

- Base the risk assessment on the principals of ALARP (as low as reasonably practicable).

- Should be an ongoing process of continuous improvement/risk reduction.

- Treat the risk assessment as a live document and review it annually as a minimum.

- Conduct a risk assessment if an incident/accident or near miss occurs, when there is a change to process or method, when new individuals are involved in a task and when there is a change to work location or office.

|

Guidance: You may not be able to deal with all hazards/risks at one time, in which case you should:

It is important to prioritise and resolve the most important hazards/risks first. It is useful to make a checklist of actions and mark them as complete when they are finished. |

Training in completing a risk assessment is available to book from the Organisational Development webpage. However, in exceptional circumstances, it may be possible to arrange training upon request to meet the needs of individual Faculties and Service Departments. Further advice and assistance is available from the Health and Safety Department.

There are no exceptions to this policy.

The University may change this Policy at any time, and where appropriate. Where a policy is not due for review, but is found to require updating, it will remain published, unless the reasons for review render it obsolete.

Further guidance can be found on the Health and Safety Department website.

https://www.wlv.ac.uk/staff/services/hsd/policies-procedures--forms/

Further information on risk assessment can be viewed on the HSE website:

http://www.hse.gov.uk/risk/index.htm

For general queries, please contact the University Health and Safety Department at HSDEmails@wlv.ac.uk

For queries regarding compliance with this policy, please contact compliance@wlv.ac.uk

|

VERSION |

7 |

AUTHOR(S) OWNER |

Head of Health and Safety Director Health, Safety and Resilience |

|

Approved Date |

10 January 2023 |

Approved By |

University Executive Board |

|

Review Date |

10 January 2026 |

|

|

.png)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-18-19/iStock-163641275.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/250630-SciFest-1-group-photo-resized-800x450.png)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-18-19/210818-Iza-and-Mattia-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images/Maria-Serria-(teaser-image).jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-2024/241014-Cyber4ME-Project-Resized.jpg)

/prod01/wlvacuk/media/departments/digital-content-and-communications/images-18-19/210705-bric_LAND_ATTIC_v2_resized.jpg)